Insulation jackets

Easiest way to insulate your armature

Your armature in your system is not insulated? Don’t worry, you are not the only one. Luckily we have easy solution to help you. Safety and huge amount of heat losses are the main things which happen when valves are not insulated. It is not reasonable to insulate them in a way like rest of your piping is done because armature need maintenance. The most cost-effective way is to use insulation jackets.

We can offer your insulation jackets for globe valves, steam traps and strainers. Jackets have 10 mm pyrogel insulation which can tolerate up to 230C.

Insulation jackets for globe valves

| JGV10015F2 | Jacket for Globe Valve DN15, Type II, pyrogel 10mm, up to 230C |

| JGV10020F2 | Jacket for Globe Valve DN20, Type II, pyrogel 10mm, up to 230C |

| JGV10025F2 | Jacket for Globe Valve DN25, Type II, pyrogel 10mm, up to 230C |

| JGV10032F2 | Jacket for Globe Valve DN32, Type II, pyrogel 10mm, up to 230C |

| JGV10040F2 | Jacket for Globe Valve DN40, Type II, pyrogel 10mm, up to 230C |

| JGV10050F2 | Jacket for Globe Valve DN50, Type II, pyrogel 10mm, up to 230C |

| JGV10065F2 | Jacket for Globe Valve DN65, Type II, pyrogel 10mm, up to 230C |

| JGV10080F2 | Jacket for Globe Valve DN80, Type II, pyrogel 10mm, up to 230C |

| JGV10100F2 | Jacket for Globe Valve DN100, Type II, pyrogel 10mm, up to 230C |

| JGV10125F2 | Jacket for Globe Valve DN125, Type II, pyrogel 10mm, up to 230C |

| JGV10150F2 | Jacket for Globe Valve DN150, Type II, pyrogel 10mm, up to 230C |

Insulation jackets for strainers

| JST10015F2 | Jacket for Strainer DN15, Type II, pyrogel 10mm, up to 230C |

| JST10020F2 | Jacket for Strainer DN20, Type II, pyrogel 10mm, up to 230C |

| JST10025F2 | Jacket for Strainer DN25, Type II, pyrogel 10mm, up to 230C |

| JST10032F2 | Jacket for Strainer DN32, Type II, pyrogel 10mm, up to 230C |

| JST10040F2 | Jacket for Strainer DN40, Type II, pyrogel 10mm, up to 230C |

| JST10050F2 | Jacket for Strainer DN50, Type II, pyrogel 10mm, up to 230C |

| JST10065F2 | Jacket for Strainer DN65, Type II, pyrogel 10mm, up to 230C |

| JST10080F2 | Jacket for Strainer DN80, Type II, pyrogel 10mm, up to 230C |

| JST10100F2 | Jacket for Strainer DN100, Type II, pyrogel 10mm, up to 230C |

Insulation jackets for steam traps

| JFT10040F2 | Jacket for Float Trap DN40, Type II, pyrogel 10mm, up to 230C |

| JFT10050F2 | Jacket for Float Trap DN50, Type II, pyrogel 10mm, up to 230C |

Industrial plug and play substations

Steam boilerhouse watermonitoring package

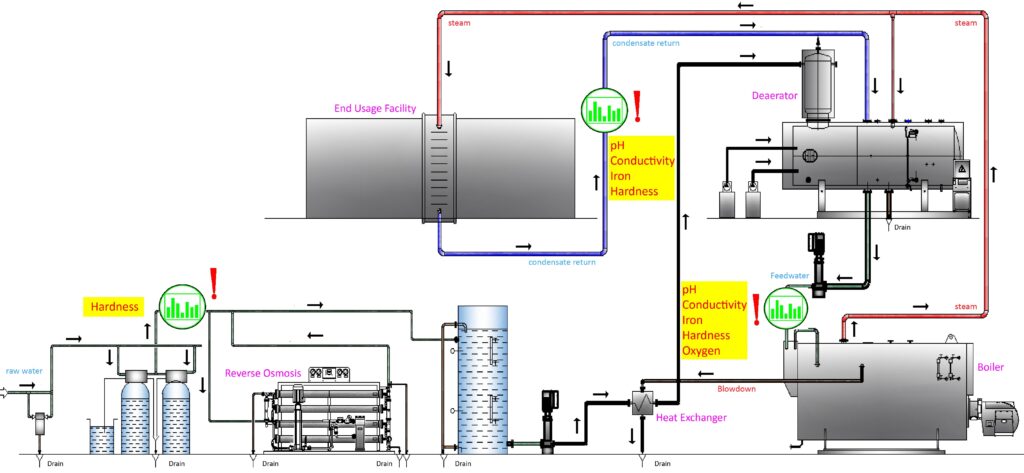

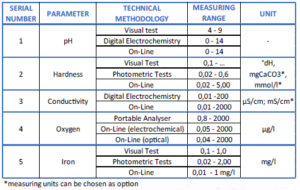

A steam boiler house is a complicated system where several elements need to be appropriately synchronized to achieve desired outputs consistently and sustain the overall life-cycle. Out of them, the role of water quality is significant. It is necessary to monitor the water control parameters at critical positions along the system design, else, any deviation from expected values over time can accelerate the process of drop in thermal fficiency, elevated corrosion risk, rise in operational expenses and reduced life expectancy.

The WATER MONITORING PACKAGE solution from  SAVERY is a customizable system design meant to measure and provide feedback at the specified points on the respective water parameters. Accurate and regularized analysis at these junctures

SAVERY is a customizable system design meant to measure and provide feedback at the specified points on the respective water parameters. Accurate and regularized analysis at these junctures

leads to an overall optimized thermal efficiency, availability and reliability of the boiler house from a water quality perspective.

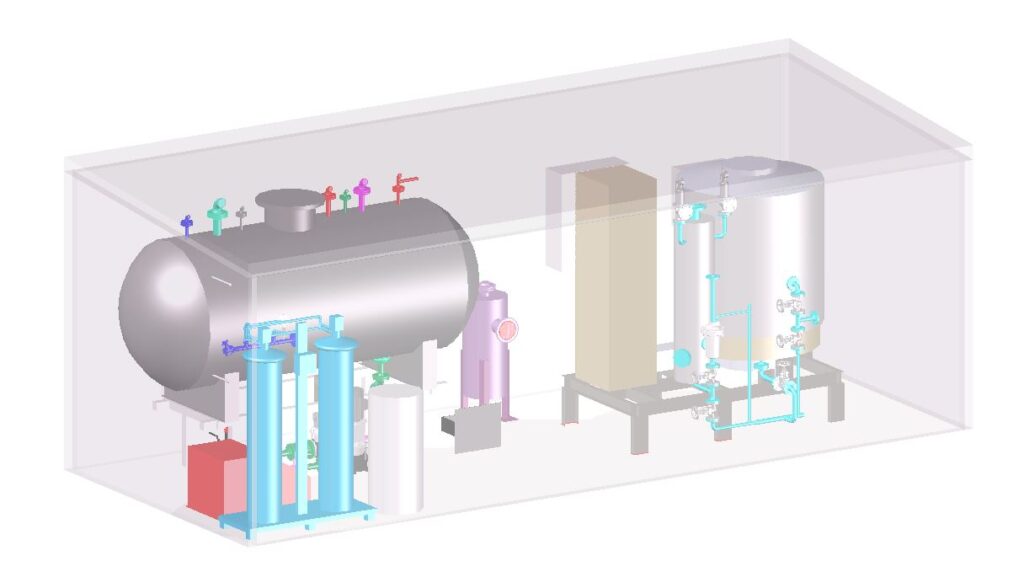

Containerized custom made solutions

SAVERY has capability to design and manufacture different types of complex containerized boilerhouses, watertreatment plants and other process parts like substations and heat pumps.

This specialized design is ideally suited for customers across a variety of industries

who are in need of steam/hot water for their processes and would like to address

issues such as back-up for their existing installation, need deliverables at remote

spots or eliminate the idea of having a rigid standalone system in totality.